|

Yttrium thin films are suitable for x-ray mirrors, photocathode emitters in e-beam lithography, electron microscopes and free-electron lasers.

Yttrium oxide (Yttria, Y2O3) dielectric film, protective film produced by reactive magnetron sputtering (RMS) is a promising ceramic material for electronic and optical applications due to its excellent properties, such as high refractive index, large band gap, excellent thermal conductivity, a low dominant phonon energy and broad transparency range.

Corrosive halogen gas is used in Reactive Ion Etching (RIE), PECVD, and Plasma Etch processes of semiconductor manufacturing, so that surface of chambers and vacuum compatible substrate should have good corrosion, erosion, wear, etch resistance properties to avoid the generation of particles and contamination. Yttrium oxyfluoride (YOF Y5O4F7) ceramics are ideal plasma-resistant materials for semiconductor production equipments.

1.) Oxide sputtering target:

LaCoO3, B2O3, CeO2, CeO2/Sm2O3, CeO2/Lu2O3, CoO, Pr2NiO4, Nd2O3, MnO2, Sm2O3, HfLaO, HfAlO, Eu2O3, SrCoO3, Gd2O3, Bi1.2AlO3, Tb4O7, Li5.2Ti5O12, Dy2O3, Li1.4CoO2, Ho2O3, Sr3Al2O6, Er2O3, BaSnO3, Tm2O3, Yb2O3, Lu2O3, Sc2O3, Y2O3, Ta2O5, Ta2Ox, Nb2O5, Nb2Ox, Ga2O3, V2O5, V2O3, VO2, VOx, ZrO2 doped with Ti, WO3, WO2.9, WO3/MoO3, HfO2, MgO, MgO/Cr, Al2O3, Al2O3/Cr, In2O3, Indium Tin Oxide, ITO (In2O3-SnO2), In2O3/CaO, ZnO, Al2O3 doped ZnO (AZO), IZO (Indium Zinc Oxide, 90 wt% In2O3 / 10 wt% ZnO), In2O3/CaO ICO, Li2O/ZnO LZO, Ga2O3 doped ZnO (GZO), IGZO, ZnO2/TiO2, ZnO2/ZrO2, ZnO/Li, ZnO/Mg, ZnO/LiCl, ZnO/ZnS, La0.67Sr0.33MnO3 (LSMO), ZrO2-Y2O3 stabilized (YSZ), SnO2, Sb2O3 doped SnO2 (ATO), SnO2/F FTO, ZrO2+Ti, ZrO2+Zr, ZrO2+SiO2, Bi2O3, Bi2O3/Dy2O3/Fe2O3, Cr2O3, MoO, MoO3, NiO, NiO/Li, SiO, Cr-SiO, SiO2, TiO, TiO2, TiOx, TiO2/Nb2O5, Ti2O3, Ti3O5, CuO/Al2O3, Cu2O, Sb2O3, BaO, CaO, Fe2O3, Fe3O4, PbO, PbTiO3, PbZrTiO3, PbZrO3, PbZr0.52Ti0.48O3, PbZr0.2Ti0.8O3, Pb1.2ZrO3, LiNbO3, SrO, FeTiO3, SrTiO3, SrRuO3, BaTiO3, PbTiO3, SrZrO3, BaZrO3, SrBaTiO3, PZT (Plumbum Zirconate Titanate), LaNiO3, InGaZnO, CuInO2, LaAl2O3, CGO, Y3Fe5O12 YIG, Y2Ce1Fe5O12, Gd3Ga5O12, Tm3Fe5O12 TIG, Ce2Bi0.5Y0.5Fe5O12, Li6.4La3Zr1.7W0.3O12, Li7La3Zr2O12, HfO2, ZrO2, LiCoO2, Li3PO4, Cd2SnO4, BiFeO3, Yb2Hf2O7, Yb6HfO11, Yb4Hf3O12, Yb2SiO5, LiMn2O4, Li4Ti5O12, LiLaTi2O6, Mg2SiO4, MgFePO4, Bi2WO6, RuO2, MgMnSiO4, MgFeSiO4, NdNiO3, BaFe12O19, SiO2/Cr2O3, BaZr0.8Y0.2O3, SiO2/In2O3/ZnO, Ba0.5Sr0.5TiO3, MgCa(CO3)2, PbZr0.6Ti0.4O3, Li2WO4, Ba0.6Sr0.4TiO3, Ba0.8Sr0.2TiO3, NiCoO, BaZrO3/Y2O3/YBa2Cu3O7, Bi1.5Zn1.0Nb1.5O7, LaAlO3, LaMnO3 BZN, Bi1.1FeO3, Ba(Zr0.8Y0.2)O3, Ce2.5Y0.5Fe5O12, Yb2HfO2, Yb6HfO11, Yb2Hf2O7, Yb2O3/HfO2, BaPbO3, InMnO3, SmFeO3, SmNiO3, Bi1.05FeO3, SrFe12O19, CdTeO3, TeO2, CdO, Co3O4, Bi4(TiO4)3, LiFePO4, CoFe2O4, BaHfO3, SrHfO3

2.) (Boride, Carbide, Nitride, Fluoride, Silicide, Silicate, Sulfide, Telluride, stannate) sputtering target

AlB2, LaB6, SmB6, GdB6, ZrB2, CrB2, TiB2, HfB2, Mo2B5, TaB2, NbB2, W2B, WB, VB2, TiB, Boron

Cr2AlC, Ti2AlC, V2AlC, TiC, SiC, WC, WC-Co, WC-Ni, B4C, TaC, NbC, Cr3C2, HfC, Mo2C, VC, TeC, ZrC, Cr/Si/SiC, CrB2/SiC, Fe3C, Co2C, Ti3AlC2

Si3N4, AlN, BN, BN/SiC mixture, CrN, HfN, TaN, NbN, ZrN, TiN, VN

LaF3, CeF3, NdF3, YF3, NaF, KF, BaF2, AlF3, LiF, CaF2, SrF3, SrF2, MgF2

CoSi2, Mo5Si3, MoSi2, Ta5Si3, TaSi2, TaSi, WSi2, WSi, Nb5Si3, NbSi2, CrSi2, Cr3Si, HfSi2, TiSi2, ZrSi2

Ti5Si3, ZrSi2, WSi2, VSi2, V3Si, NiSi, YSi2, GeSi, HfSiO4, ZrSiO4

CdS, ZnS, FeS2, Cu2S, ZnS/Mn, In2S3, Sb2S3, PbS, MoS2, MoS2/Ti, MoS2/Ni, MoS2/W, SnS, SnS2, TaS2, WS2, In2S3, GeS, GeS2, Ag2S, Y2S3

CdSe, In2Se3, GeSe, GeSe2, GeSe4, GeSe6, CuSe, Cu2Se, SnSe, SeSe2, SiSe, ZnSe, Bi2Se3, WSe2, As2Se3, Ag2Se, MoSe2, HgSe, Sb2Se3

Zn2SnO4, Cd2SnO4, ZnTe, Bi2Te3, In2Te3, ZnSe, As2Te3, GeAs3Te5, GaAs, InAs

Ag2Te, Cr2Te3, GeTe, CdTe, InTe, PbTe, Bi2Te3, Ge2Sb2Te5, Cr2Ge2Te6, Fe3GeTe2, MnTe, SiTe, SnTe, WTe2, MgB2, MgB2/Mg, MoTe2, Sb2Te3, AlFe2B2, SeTe, HgTe

3.) Metal sputtering target:

Magnesium Mg, Calcium Ca, Strontium Sr, Barium Ba

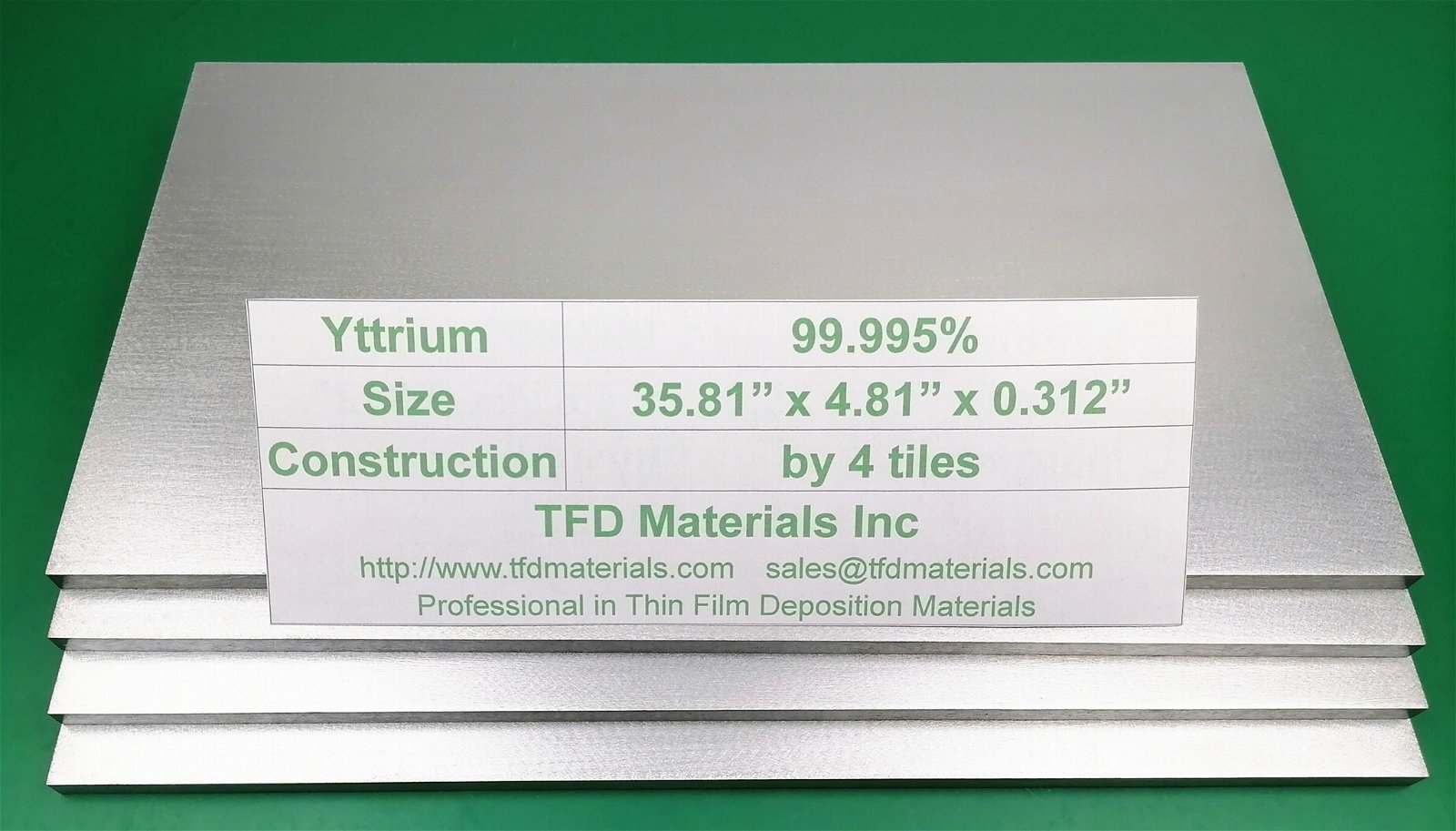

Scandium Sc, Yttrium Y, Lanthanum La, Cerium Ce, Praseodymium Pr, Neodymium Nd, Samarium Sm, Eur Eu, Gadolinium Gd, Terbium Tb, Dysprosium Dy, Holmium Ho, Erbium Er, Thulium Tm, Ytterbium Yb, Lutetium Lu

Titanium Ti, Zirconium Zr, Hafnium Hf, Vanadium V, Niobium Nb, Tantalum Ta, Chromium Cr, Molybdenum Mo, Tungsten W, Manganese Mn, Rhenium Re,

Iron Fe, Ruthenium Ru, Osmium Os, Cobalt Co, Rhodium Rh, Iridium Ir, Nickel Ni, Palladium Pd, Platinum Pt,

Copper Cu, Silver Ag, Gold Au, Zinc Zn, Cadmium Cd

Boron B, Aluminum Al, Indium In, Carbon C, Graphite, Silicon Si, Germanium Ge, Tin Sn, Lead Pb, Antimony Sb, Bismuth Bi, Selenium Se, Tellurium Te

4.) Alloy sputtering target:

Ag/Al, Ag/Cu, Ag/La, Ag/Lu, Ag/Mg, Al/Ca, Al/Ce, Al/B, Al/Sm, Ag/Sn, Al/Ag, Al/Cr, Al/Cu, Al/Cu/Zn, Al/Zn, Al/Fe, Al/Dy, Al/Tm, Al/Er, Al/Gd, Al/Li, Al/Mg, Li/Mg, Al/Mg/Si, Al/Mn, Al/Ni, Al/Sc, Al/Si, Al/Si/Cu, Al/Si/Y, Al/Sm, Al/Ta, Al/Ti, Al/Ti/Ta, Al/Mo, Al/Nd, Al/V, Al/Y, Al/Yb, Al/W, Al/Cr/Nb/Si/Ti/V, Al/Cr/Mo/Ta/Ti/Zr, Bi/Ag, Bi/Sn, Bi/Pb, Bi/Te/Se/In, Cd/Sn, La/Mn, Ba/Al, Ca/Al, Ce/Ag, Ce/Cu, Ce/Gd, Ce/Sm, Ce/Ti, Co/Al, Co/B, Co/Cr, Co/Cr/Al, Co/Cr/Fe, Co/Fe, Co/Fe/V, Co/Fe/Mn/Si, Co/Fe/Si/B, Co/Fe/B, Co/Fe/Gd, Co/Fe/Cr, Co/Ni/Fe/Cr/Al, Co/Gd, Co/Mn/Si, Co/Ni, Co/Ni/Cr, Co/Nb/Zr, Co/Ti/Sb/Fe, Co/Tb, Co/V, Co/Si, Co/Zr, Co/Zn/Mn, Cr/Al, Cr/B, Cr/Cu, Cr/Mn, Cr/Ni, Cr/Si, Zr/Si, Cr/SiO, Cr/V, Cr/W, Cu/Al, Cu/Ag, Cu/Fe, Cu/Cr, Cu/Al/Ni, Cu/B, Cu/Be, Cu/Ga, Cu/Ge, C/W, C/Ag, Cu/In, Cu/In/Ga/Se, Cu/Zn, Cu/Zn/Al, Cu/Zr/Ti, Cu/Si, Cu/Mo, Cu/Mn/Ti, Cu/Ti, Cu/Ni, Cu/NiO, Cu/Ni/Zn, Cu/Li, Cu/W, Dy/Fe, Dy/Co, Dy/Fe/Co, Fe/Al, Fe/B, Fe/Cr, Fe/Cr/Al, Fe/Co, Fe/Co/B, Fe/Co/Gd, Fe/Gd, Fe/Hf, Fe/Mn, Fe/Ni, Fe/Si, Fe/Si/Al, Fe/Zr, Gd/Ce, Gd/Fe, Gd/Fe/Co, Gd/Er/Si, Gd/Tb, Gd/Ti , Ho/Cu, Hf/Fe, Hf/Zr, Hf/Y, Hf2Al5, HfAl3, In/Sb, In/Sn, In/Zn, Fe/Ge, Pb/Bi, LaB6, La/Al, La/Ni, Mg/Al, Mg/Ca, Mg/Dy, Mg/Gd, Mg/In, Mg/Nd, Mg/Ni, Mg/Nd/Zr/Y, Mg/Sc, Mg/Sm, Mg/Si/Bi, Mg/Y, Mg/Y/Al/Zr, Mg/Zr, Mg/Zn, Mg/Zn/Ca, Mn/Co, Mn/Ga, Mn/Ge, Mn/Co/Ge, Mn/V/Si/Co, Mo/Co/Si, Mn/Al, Mn/Fe, Mn/Ni, Mn/Sn, Mn/Ti/Al, Mo/Na, Mo/Nb, Mo/Cr, Mg2Ni, Ta/Mo, Mo/Si, Nb/Cr/Ti, NbAl3, Nb3Al, Nb2Al, Nb/Si, Nb/Ti, Nb/Zr, Nb/Ta/Ti/V, Nd/Ag, Nd/Fe/B, Ni/Al, Ni/Al/Cr/Hf/Si, Ni/Ce, Ni/La, Ni/Cu, Ni/Cr, Ni/Cr/Al, Ni/Cr/Si, Ni/Ga, Ni/Fe, Ni/Mn, Ni/Ti, Ni/W, Ni/C, Ni/V, Ni/V/Zr, Ni/Yb, Ni2Yb, Ni2MnAl, Co2MnSi, Ni3Yb, Ni3Ti, Ni/Yb, Ni/Zr, Ni/Co, Ni/Re, Ni/Co/Cr/Al/Y/Hf/Si, Sc/Ni, Sc/Zr, Sm/Co, Sm/Fe, Sm2Fe17, Sm/Zr, Sn/Mn, Sn/Sb/Ta, Si/Ti, Ta/Al, Ti/Al, Ti/Ag, Ti/Al/Cr, Ti/Al/Nb, Ti/Al/W, Ti/Al/Cr/Nb, Ti2Al, Ti/Al/Y, Ti/Al/V, Ti/Co, Ti/Hf, Ti/Cr, Ti/Cr/V, Ti/Cr/Mn, Ti/Ni, Ti/Si, Ti/Zr, Ti/Zr/Cr/Mn, Ti/Zr/V, Ti/Pd, Ti/Mo, Ti/Mn, Ti/Mo/Zr/Fe, Ti/V, Ti/V/Cr, Ti/W, Ti2MnAl, Tb/Dy, Tb/Dy/Fe, Tb/Fe, Tb/Fe/Co, Tb/Gd/Fe/Co, Si/Al, Si/Al/W, Si/Cu, Si/Er, SiGe, Si/Ge, Si/Zr, Ge/Si, Ge/Ni/Ti/Cr/Si, V/Al, V/B, V/C, V/Co, V/Cr, V/Cu, V/Fe, V/Mo, V/Ni, V/Ti, V/Ti/Cr, WAl4, Re3Al, W/Cr, W/Ti, W/Si, W/Si/C, W/Ta, Y/Al, Y/Ti, Y/Zr, Y/Zr/Mg, Y/Zr/Si, Cu6Sn5, Cu/Zn/Sn/Se, Zn/Al, Zn/Mg, Zn/Fe, Zn/Fe/Al, Zn/Sn, Zn/Ti, Zn/Al/Mg, Zr2Si, Zr/Al, Zr/Ce, Zr/Co/Ce, Zr/Cu, Zr/Fe, Zr/Cu/Al, Zr/Gd, Zr/Si, Zr/Ti, Zr/Ni, Zr/Y, Zr/Mn/Fe/Al, W/Re, W/Re/HfC, Ti3Al, TiAl3, TiAl6V4, Co2MnGa, In/Sb, Co2MnSi, Nb3Sn, Nb3Ge, Zr2Cu, Zircaloy-4, SmFe11Ti, CeCu6, B/Ni/Co

5.) Thin film photovoltaic coating materials

Cadmium Sulfide CdS, Copper Sulphide CuS, Cadmium Telluride CdTe, Lead Telluride PbTe, Mercury Telluride HgTe, Indium Telluride In2Te3, Antimony Telluride Sb2Te3, Bismuth Telluride Bi2Te3, Gallium Telluride Ga2Te3, Tin Telluride SnTe

Zinc Telluride ZnTe, CuInGaSe, In2Se3, Ga2Se3, CuInSe2, CuInS2, Zinc Stannate (Zn2SnO4), Cadmium Stannate (Cd2SnO4), SnO2, SnCl4, ZnO, Molybdenum, Indium, ZnS, ZnSe, InSb, InAs, In2S3, CuGa, Cu2S, Cu2Se.

Lanthanum Hexaboride (LaB6) products:

Used as a high brightness thermionic emission materials because of its low work function, high melting point and high metallic conductivity. LaB6 cathode for Leybold 1104 coating machines for precision optical coating is our advantage.

We produce LaB6 powder, LaB6 disc, LaB6 tablet, LaB6 target, LaB6 rod, LaB6 crucible, LaB6 sector ring, LaB6 tube (hollow cathode), YB6 rod, CeB6, PrB6, NdB6, SmB6, EuB6, GdB6, TbB6, DyB6, HoB6, ErB6, TmB6, YbB6, LuB6, ScB6, (LaBa)B6, (LaEu)B6, CaB6, etc.

|